Find A Dealer

You've Reached The

Dewpoint

You've Reached The

Dewpoint

Staheli West's lineup of DewPoint hay steamers offers a revolutionary solution for the agricultural industry by significantly enhancing the quality of baled hay. By utilizing advanced steam technology, the DewPoint machines raise the moisture content of dry hay to an optimal level.

Steaming hay during baling has many benefits:

Bale High Quality Hay 12-24 Hours a Day with a DewPoint Hay Steamer

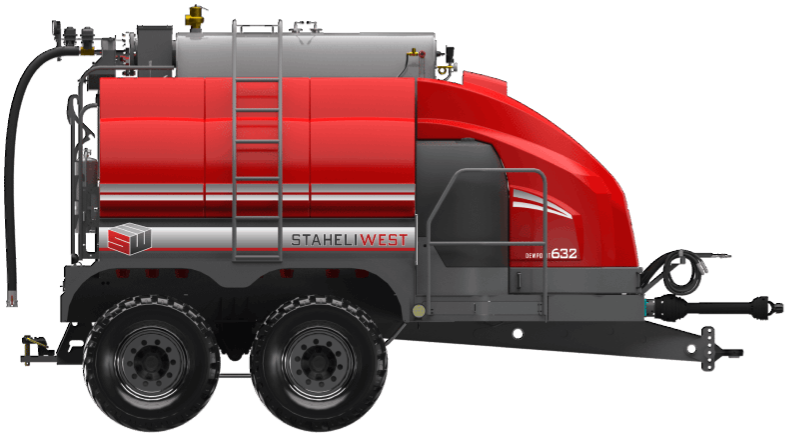

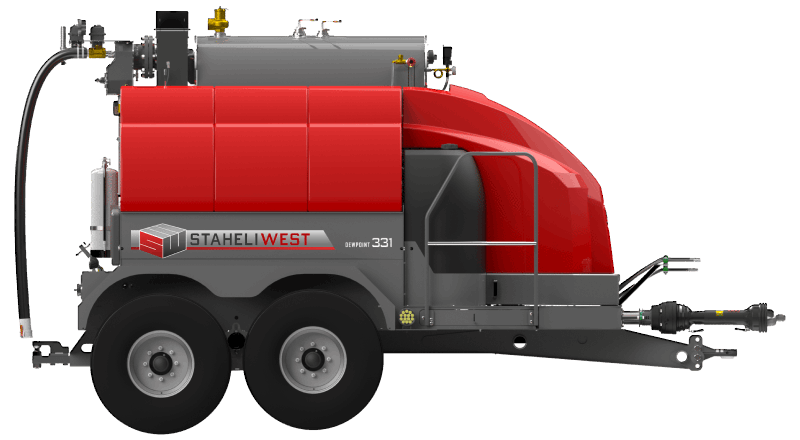

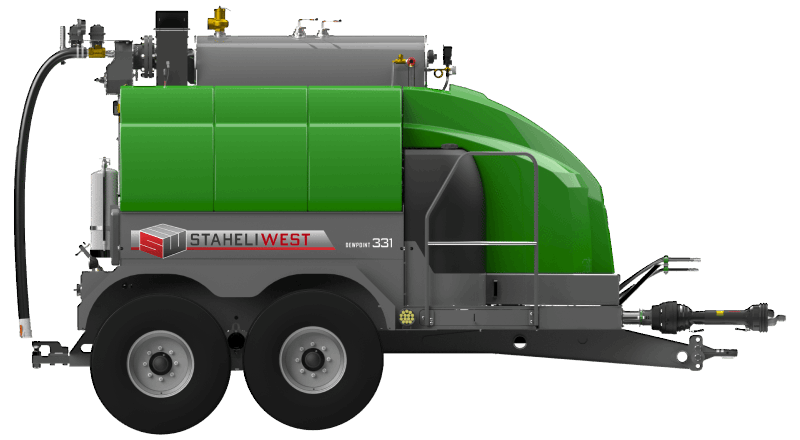

Our

Products

Being able to bale with steam when the hay is ready opens up the baling window and increases productivity and efficiency. We offer two different models of DewPoint machines that are compatible with all major makes and models of balers.

How It Works

The DewPoint machine generates steam using a low-pressure boiler system. University studies have shown that using steam to bale hay reduces leaf loss by 58% compared to natural dew.

More On The Science

Download the University of Wisconsin Study

Get the Study

Our Story

Making dew

The Story of How it All Started

"A Taco

Restaurant"

That’s where the idea to apply steam to hay came from. Watch the entire inspirational and miraculous story of how it all started.

Watch Full Story

What Are Our Customers Saying?

At Staheli West, we take great pride in providing exceptional products and services that change our customers’ operations and lives for the better. Don't just take our word for it; hear what some of our customers have to say about their experience with us and the steamer.

Watch More Steamer Stories

Revolutionize Your Operation

Learn More